Strategic Location:

Chengdu International Railway Port (Asia’s Largest Rail Container Hub), Sichuan, China

Core Functions:

Import Meat Inspection & Quarantine Storage

Bonded Cold Chain Logistics

-25°C Deep Frozen Storage

Project Scope & Compliance

Capacity: 5,000-ton (30,000m³) frozen meat storage

Regulatory Standard: China Customs CIQ (Inspection & Quarantine) Certification

Technical Highlights

1.Premium Refrigeration System

Primary Freezers:

BITZER Piston Unit (30HP, Top-Discharge Cabinet)

Chilled Storage:

Emerson Copeland™ Scroll Compressor Unit (15HP)

Key Advantage: Dual-system redundancy ensures uninterrupted operation during customs inspection cycles.

2.Optimized Storage Environment

Air Circulation: 2x High-Efficiency Forced-Air Evaporators

Achieves ±0.5°C uniformity in 30 mins after door opening

Thermal Envelope:

200mm EPS Sandwich Panels (Double-Sided Color Steel)

K-value ≤0.023 W/m·K (Ultra-low thermal conductivity)

Defrosting: Fully Automated Electric Heat Defrost

40% faster defrost cycles vs. standard hot gas

3.Customs-Compliant Control System

Control Panel: Imported Modular Touchscreen HMI

Critical Features:

Real-time temperature mapping for customs audit trails

Automated alarm forwarding to CIQ authorities

Dual power supply monitoring (ISO 22000 compliant)

Operational Status

Completed & Certified by China Customs (Dec 2015)

Operational with zero quarantine incidents since handover

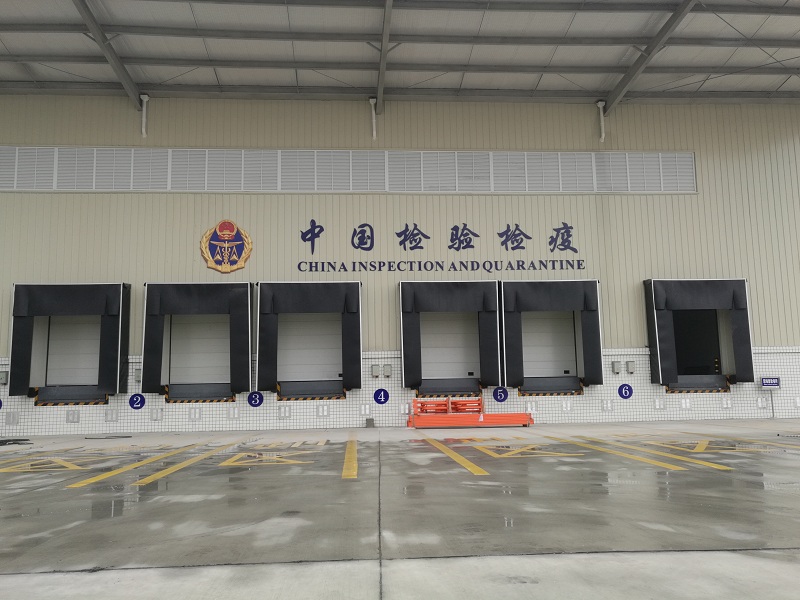

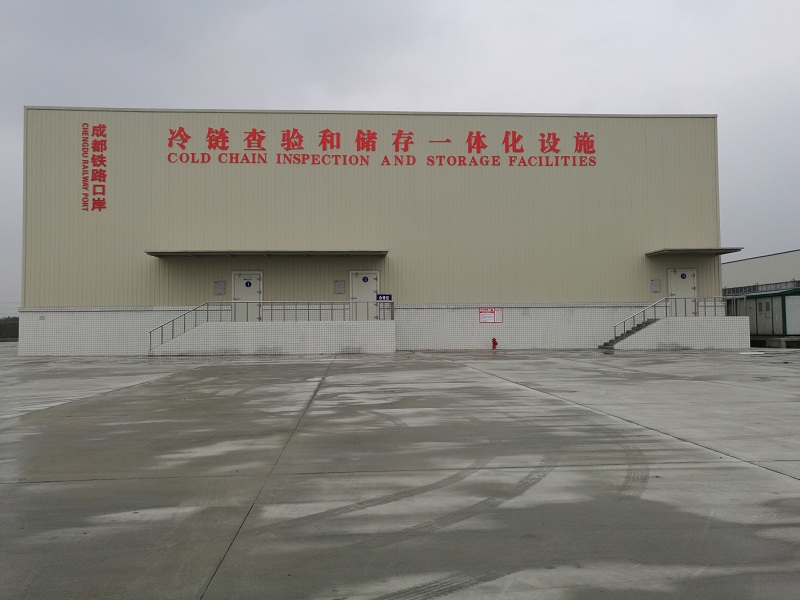

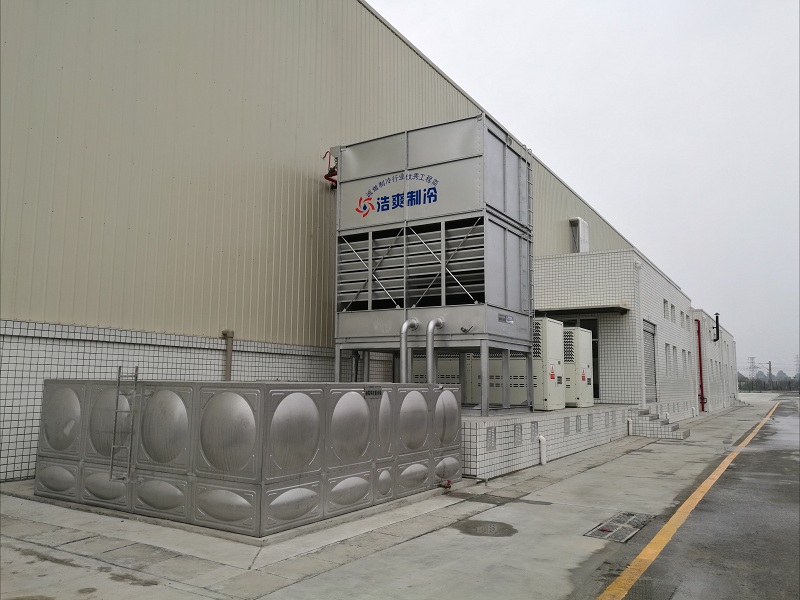

Construction & Completion Photos

Real shot of the cold storage platform for cold chain logistics at Chengdu Railway Port in China

External shot of the cold chain logistics cold storage at Chengdu Railway Port in China

Cold chain logistics cold storage completed real shot

Cold chain logistics cold storage completed real shot

Cold chain logistics cold storage completed real shot

BITZER Refrigeration Unit

China cold storage solution provider

China cold storage solution provider