Project Overview

In May 2024, Zhuohao Agricultural Technology Co., Ltd. (Guizhou, China) completed the construction of a 5,000 m³ chili cold storage facility. The project consisted of three independent cold rooms, designed to maintain storage temperatures between -5°C and +8°C, meeting strict energy efficiency and URS (User Requirement Specification) standards.

Engineered Solution

1. Intelligent Refrigeration System

- Core Components:

- 3 × Emerson Copeland™ ZPS25KQE scroll compressors (25HP each)

- Eco-friendly R448A refrigerant (GWP=1273)

- Danfoss™ electronic expansion valves

- Energy Optimization:

- Variable frequency drives (VFD) reduce compressor cycling losses

- Hot gas bypass defrost cuts 40% energy vs electric defrost

2. Insulation & Panel System

- Material: 100 mm polyurethane double-sided color steel panels

- Fire resistance rating: Class B1 (flame-retardant)

- Provides excellent thermal insulation and durability, ensuring long-term stability.

- Doors: Electric sliding doors, polyurethane-filled, aluminum alloy frame, 0.5 mm double-sided color steel surface

- Anti-lock safety design

- Integrated electric heating to prevent condensation

- Emergency alarm system for safety

- Air Curtain: Yongxing Diamond high-speed air curtain (2300 mm), powder-coated casing, pure copper motor (220V)

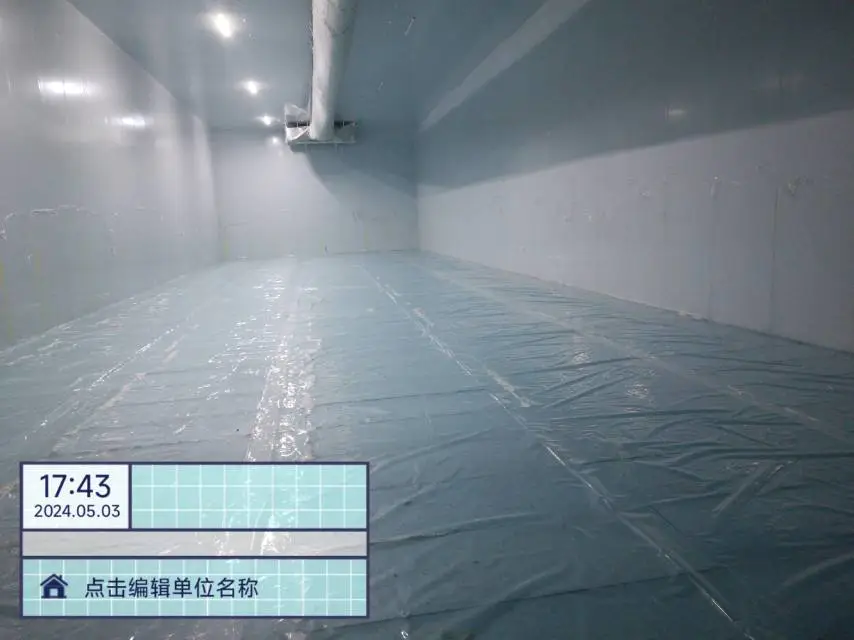

Construction & Completion Photos

Workers installing cold storage panels

Workers installing cold storage panels

Workers installing cold storage panels

Lifting refrigeration equipment

Install cold storage door

Installing XPS extruded board

Installing XPS extruded board

China cold storage solution provider

China cold storage solution provider